In a rapidly expanding urban landscape and the ever-demanding need for new and innovative construction techniques, the use of insulation has become a crucial aspect in ensuring sustainable and energy-efficient buildings. Back in the day, this was a relatively simple process of filling gaps and cracks with materials such as straw, mud or cork. But these somewhat primitive methods have evolved into highly specialised and efficient solutions, which ultimately raise the bar for modern-day construction.

Among the potential solutions, one that has gained significant traction in the industry is the highly durable and versatile 70mm PIR insulation. Given the widespread use and the positive impact it has on building structures, it is worth delving deeper into the science behind this innovative material.

What Is 70mm PIR Insulation?

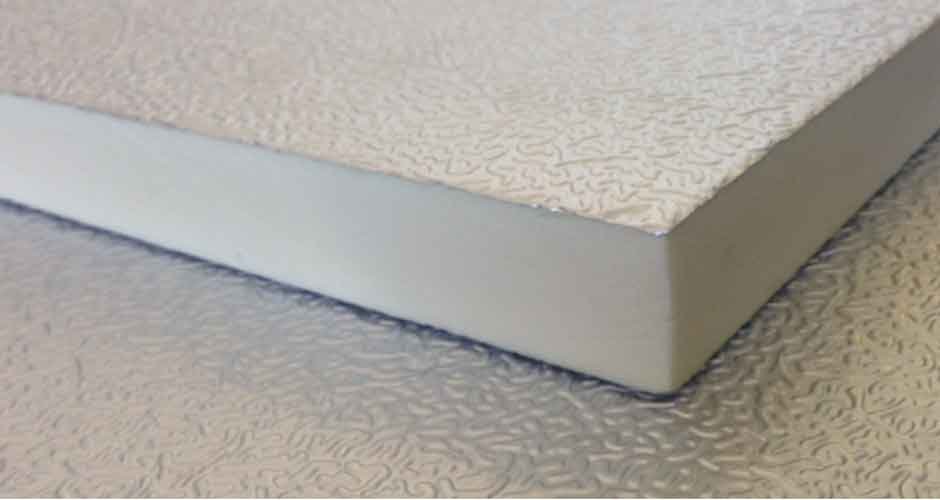

You might be wondering how this particular form differs from all the other insulation options available in the market. Well, for starters, PIR stands for Polyisocyanurate foam insulation board and is renowned for its high thermal resistance properties. It is a closed-cell rigid foam product that has been around since the late 1940s but has undergone significant advancements to turn into a highly effective and efficient insulation option.

The key ingredient in producing PIR is a combination of isocyanates and polyols, which are heated and mixed together to create a thermosetting polymer. This process results in the closed-cell structure that makes PIR stand out from other materials like polystyrene or mineral wool. As such, it does have a higher thermal resistance and can keep heat in or out more effectively.

What Can You Use 70mm PIR Insulation For?

The sheer versatility and durability of this material bring more to the table than just traditional insulation methods. Even if you already have insulation in your building, switching to 70mm PIR can offer additional benefits that can ultimately save you time, money and energy.

Improving Energy Efficiency

Given its exceptional thermal resistance properties, 70mm PIR insulation is ideal for improving the energy efficiency of buildings. It can be used in walls, floors and roofs to minimise heat transfer between a building’s interior and exterior, ensuring comfortable temperatures all year round. Depending on the thickness and application, PIR insulation can significantly reduce energy consumption and lower utility bills.

With this in mind, the general public, especially in colder regions or countries with extreme climate conditions, has started to embrace the use of this material for both residential and commercial buildings. While it does require a larger upfront investment, the long-term benefits in terms of energy savings are what turn it into a worthwhile choice.

Noise Pollution From External Sources

Another benefit that comes with using these kinds of boards is the reduction of external noise in buildings. PIR insulation can effectively dampen sound transmission, making it an excellent choice for buildings located in busy or noisy areas. The closed-cell structure acts as a barrier that blocks out unwanted noise, ensuring a peaceful and quiet indoor environment.

If you live in an area with heavy traffic, near airports or industrial sites, it can make a significant difference in reducing noise pollution and providing a more comfortable living or working space. Imagine being able to sleep soundly without street noises or conducting meetings without any outside distractions.

Thermal Insulation for Piping and Ductwork

The water and ventilation systems in buildings are the foundation of a well-functioning structure, yet they are often overlooked when it comes to insulation. If you think about it, these systems run through the entire building and can result in significant heat loss or gain if left uninsulated.

Water systems in particular are vulnerable to temperature changes, which can lead to condensation and even burst pipes in extreme cases. When each section of the piping is properly insulated, it can prevent heat transfer and maintain consistent temperatures, ensuring the smooth operation of these systems.

As for the ducts, they are responsible for distributing heated or cooled air throughout a building. Uninsulated ductwork can result in significant energy loss and uneven heating or cooling, which can certainly affect comfort levels and energy bills. With 70mm insulation, air can be effectively contained within the system, minimising leakage and maintaining the desired temperature.

Cold Storage Facilities

In addition to its application in buildings, PIR insulation is also used in cold storage facilities. These types of buildings require a constant and controlled temperature to preserve the integrity and quality of perishable goods like food, pharmaceuticals or other temperature-sensitive products. PIR insulation’s thermal resistance properties make it an ideal choice for cold storage, reducing the energy required to maintain low temperatures while keeping the internal environment stable.

When there’s a constant and consistent temperature, it minimises the risk of spoilage or damage to goods, which ultimately saves costs and ensures customer satisfaction. This cycle of reduced energy consumption and maintenance costs leads to a more sustainable operation in the long run.

Installation Techniques for Different Applications

Depending on the specific application, there are different techniques for installing 70mm PIR insulation effectively. The two most commonly used methods are adhesive bonding and mechanical fixing, and the one you opt for will be based on factors such as the building’s structure, condition and intended use.

Adhesive Bonding

This method involves glueing PIR boards directly onto a surface using an adhesive. It is a quick and easy installation process that can also provide additional structural support and reduce air leakage. However, it may not be suitable for large areas or surfaces with irregularities since the adhesive may not bond correctly. Even if the surface is smooth, it may require additional preparation to ensure proper adhesion.

Mechanical Fixing

Mechanical fixing involves securing PIR boards to a surface using mechanical fixings such as screws or clips. This method is more time-consuming than adhesive bonding but offers greater stability, making it suitable for larger areas and surfaces with irregularities. It is also ideal for projects that require strict fire safety regulations since some mechanical fixings have fire-resistant properties. It doesn’t require any additional preparation of the surface, which means less time and effort spent on installation.