Diffractive optical elements are unique optical elements that are often called computer-generated holograms (CGH). These optical elements help shape the laser beams by harnessing the wave nature of the beams. So, why do we need to change the light beams? This is because the distribution pattern that most laser beams have is a Gaussian distribution pattern. This distribution has no sharp or distinct edges. As a result, mathematically the irradiance value will never become zero, causing a substantial energy loss. Therefore, when it comes to utilizing laser beams for a variety of applications, including medical treatments, imaging, sensing, material processing, printing, additive manufacturing, and communications, we need to shape the laser beams using DOEs so that the beams have a tailored distribution with distinct edges.

DOEs follow the principle of diffraction to change the laser beam’s shape. The optical elements have micro-structures that are suitable to alter the profile, amplitude, and shape of the incident beam. Nowadays, the technology advancement has helped foster efficient DOE fabrication and opened the door for plenty of new possibilities.

Important Characteristics of DOEs

Diffractive optical elements or DOEs are relatively lightweight, thinner, and smaller than refractive optical elements. This is why it is possible to integrate these optical elements easily. Some other important characteristics of DOEs include excellent compactness and longevity. A tight angular tolerance of effectively zero angular deviations is also a charactaristic of DOEs. There are different materials, including Zinc Selenide, Germanium, Polymers, and Fused Silica that are used as the substrate to manufacture diffractive optical elements, each suitable for different wavelengths and applications.

Applications

Two crucial areas where you can find the use of DOEs are – I) Beam Shaping, and II) Beam Splitting.

I) Beam Shaping

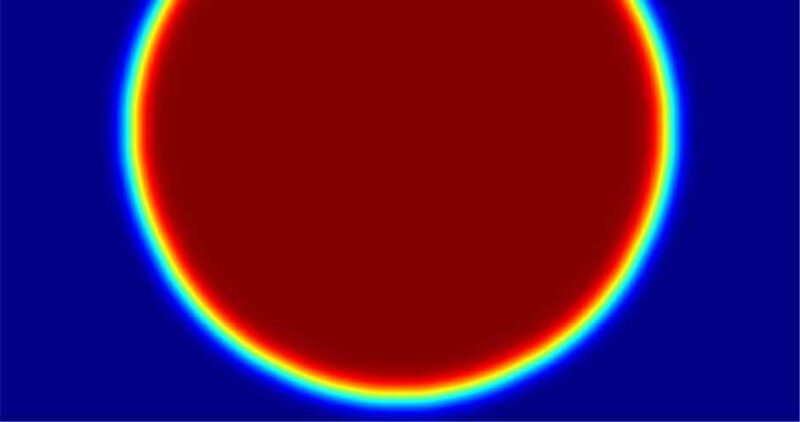

Diffractive Opticl Elements (DOEs) are useful for shaping light beams and introducing well-defined structure and order into the incident light. They are highly effective in producing precise spot shapes, including squares, lines, and circles, and find essential applications in fields such as 3D imaging, spectroscopy, and medical diagnostics. Three common DOEs that are useful for precise beam shaping are analytical beam shapers, diffractive diffusers, and broadband diffusers.

II) Beam Splitting

Beam-splitting Diffractive Optical Elements (DOEs) help split or break up an incoming light beam into many output beams, each with precisely tailored intensities. These optical elements can shape the resulting beam array patterns into diverse forms, whether it be lines, squares, circles, hexagons, or any envisioned configuration. Beam-splitting DOEs are essential for various applications, including laser micromachining, laser scribing, and medical aesthetic procedures. Moreover, these DOEs can be fine-tuned to meet specific requirements, encompassing desired intensity levels, number of orders, separation angles, and a broad range of wavelengths spanning from ultraviolet to the infrared spectrum.

DOEs also serve Beam Foci elements and have crucial applications in light-sheet microscopy, laser glass cutting, and cytometry.